![]()

NKR31525 is a lightweight Dennis fitted with their

first unit construction (engine and gearbox mated together) power unit. In later

years this model has been called the Dennis 'Ajax' although at the time of

inception it was called the '250 Gallon' model - referring to the pumping

capacity of this machine.

NKR31525 returned home this month (August 2000) after spending the last 73 years in South Africa. It was exported by Dennis in 1927 to the Benoni Fire Brigade which is a provence of Johannesburg. Some time during its operational life the foam extinguishers were replaced by four 'Alert' 3 gallon water fire extinguishers. A pitchfork and ceiling hook were fitted on either side of the chassis rails and these still remain. After it was withdrawn from service it eventually ended up in the Scharinghuisen collection at Ladysmith as part of the largest collection of preserved vintage vehicles in Africa.

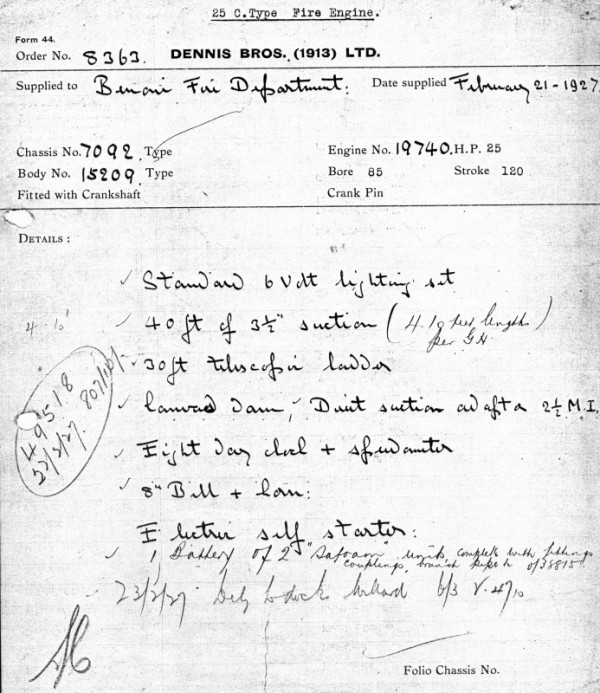

Reproduced by permission of Alexander-Dennis and the Surrey History Service

The factory build sheet shows the fittings required by the Benoni Fire Brigrade, which included an Eight day clock, an electric self starter and 'SAFOAM' foam extinguishers. The total cost which was invoiced under invoice number 49518, was £807 10 shillings.

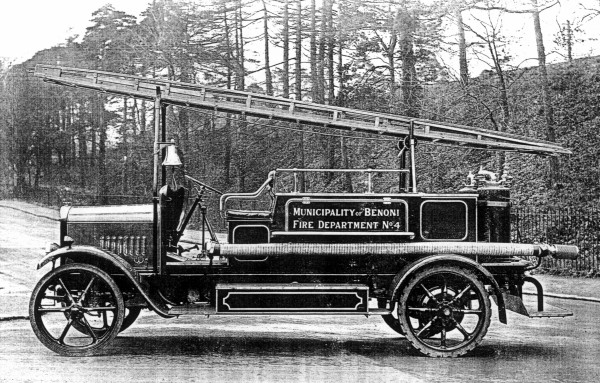

Reproduced by permission of Alexander-Dennis and the Surrey History Service

This photograph was taken outside the Dennis Guildford factory just prior to the machine being driven down to the docks. On the embankment above the road runs the main railway line to London. The 'SAFOAM ' extinguishers can clearly be seen on the rear platform. The solid rubber rear tyres exhibit a substantial block tread pattern to improve grip. The brake pedal extends well forward of the clutch and accelerator pedals a characteristic which exists today.

The engine is very compact. It is a sidevalve unit of 3 litres and runs extremely sweetly. It has the luxury of a 6 volt electric self starter and a dynamo for re-charging the battery! The maximum charging current is 6 amps although the current drain with the headlamps on is 16 amps. Hopefully it did not have to go to many fires during the night.

This pictures shows the small 4 speed gearbox with power take off to the Dennis number 2 pump. The rear brake control shaft runs transversely behind the gearbox. Each rear wheel has 4 brake shoes, 2 for the handbrake and two for the foot brake. Steel rods connect the brake shoe operating arms to the brake control shaft which links the brakes on either side. The 10 gallon petrol tank is attached to the scuttle and gravity feeds the carburettor.

To keep the engine cool whilst pumping, pump water is fed into the engine's cooling circuit. The excess drains away through the radiator overflow. This can clearly be seen in the above photograph. The filtering of the pump water before it reaches the engine is only through a rudimentary metal gauze debris filter. Consequently any dissolved solids (like river mud) settle out into the engine and radiator. The radiator tubes of NKR31525 were completely blocked when it arrived back from South Africa. In addition the engine water pump impeller has been reduced to a central stub both by corrosion and by the pumping of an abrasive mixture of water and mud.

IF ANY SOUTH AFRICAN READER HAS ANY PICTURES OF THIS MACHINE IN SERVICE OR ON DISPLAY, I WOULD BE DELIGHTED TO SEE THEM!

![]()