With everything back together, the hope was that all the engine maladies would be behind us. This was not to be the case. When the engine ran there was a pronounced clank which on reflection was also present prior to the strip down.

The source of the clank was difficult to identify by conventional means. Listening through a stethoscope produced no conclusive results although it did appear that the clank was emanating from block possibly in the region of the middle cylinders. Once more the solution was to apply science to the problem.

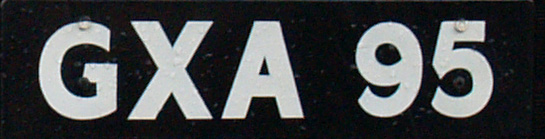

At TDC a reflective strip was glued to to the flywheel. An infra-red opto sensor was then positioned to that an electronic marker signal was generated for every flywheel revolution.

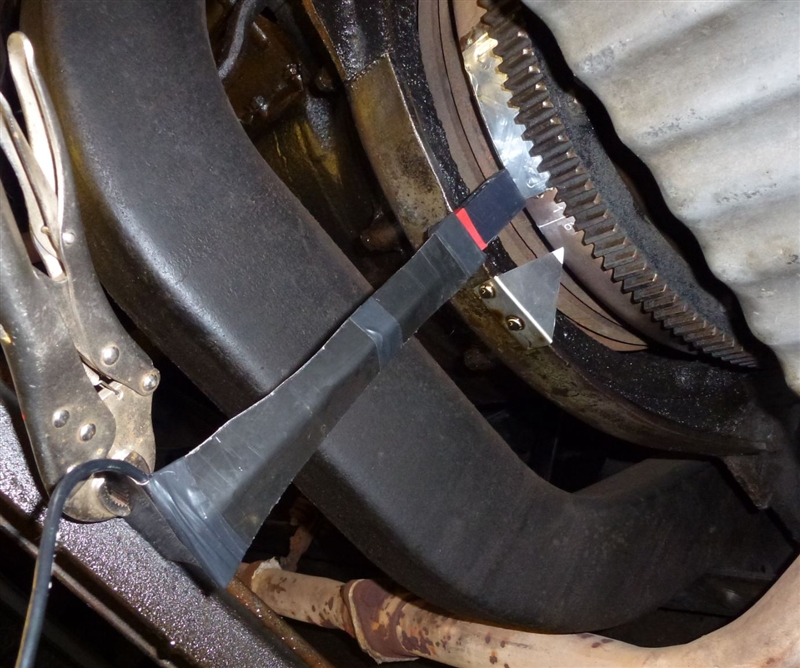

This marker signal was then fed into one channel of an audio recorder with a microphone connected into a second channel o record the engine noise complete with clank. A digital 'NAGRA' recorder was used which uses a SD memory card as the recording medium. When the recording was analysed using a PC waveform display programme the result was staggering.

The lower trace shows the engine noise with the pronounced clank every other revolution The clank occurs after ignition on the number four cylinder firing stroke. Number four cylinder of course was the cylinder which contained the cleaned up piston.

Click HERE to continue the restoration story